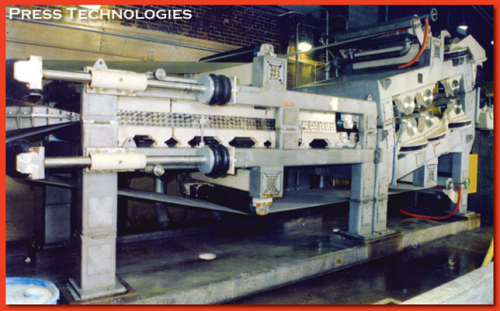

PRESS TECHNOLOGIES model WT/PP TWIN WIRE PRESS is designed to accomplish the continuous dewatering of various kinds of industrial pulps and slurries by entrainment between two porous synthetic membranes (belts). The press is of cantilever design, and will accommodate either endless or seamed belts.

The belts are supported by either perforated plastic dewatering plates or free turning rollers throughout the unit. General construction is to the same high quality standards as other PRESS TECHNOLOGIES equipment – designed for continuous industrial service.

The WT/PP TWIN WIRE PRESS has two distinct dewatering zones or sections; the wedge section and the high pressure, or nip section. The sections perform as follows:

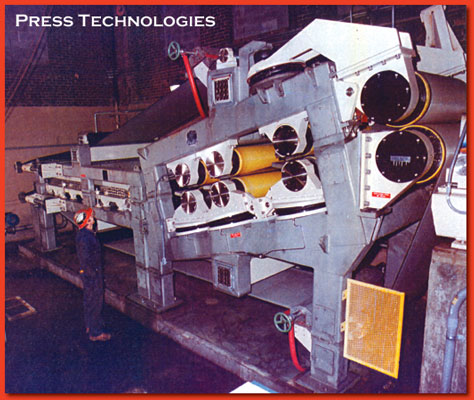

The material to be dewatered enters the Wedge Section through a pressurized stainless steel headbox which injects the suspension between the upper and lower belts. The belts are supported by dewatering plates in the initial portion of the wedge, with side sealing accomplished by a patented urethane and stainless steel side sealing system.

Dewatering Plates give way to Deflection / “S” rolls toward the end of the Wedge Section, allowing for some slight wrapping of the entrained suspension for increased pressure prior to entering the nip section. The rapid reduction of area as the material travels down the wedge results in a high rate of thickening, forming a stable sheet which then transfers into the Primary Press, or high pressure section of the press.

After entering the high pressure section, the material is passed through a series of individually controlled nip rolls of gradually increasing load. Pressure is applied pneumatically via Firestone air bags utilizing the exclusive PRESS TECHNOLOGIES Direct Pressure nipping system.

Nips are arranged in an upward slope to aid in water removal from the top belt, and to avoid the resuction of moisture into the sheet. Discharge occurs at the drive rolls, which can be nipped or fixed depending on the desired final consistency and the application.

After discharge the dewatered material is typically handled in one of two ways. Pulp thickened for process purposes in the mill can simply feed downward from the drive/discharge roll into a repulper, or into a breaker roll after which it is discharged onto a conveyor for transport to another part of the mill or storage area. Alternatively, the material can be handled as wet lapped pulp for storage or market use in those instances where a Cutter Layboy Unit is available and the dewatered sheet is compatible with the wetlapping process. This type of equipment is also capable of making a sheet capable of drying for producing dried market pulp.

Pulp Thickening

Pressing/Wet Lapping - Standard Line

Pressing/Wet Lapping LT Line

Cuts the Sheet And Creates Pulp Bales