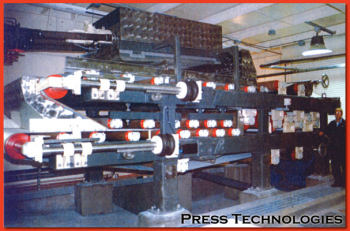

The PRESS TECHNOLOGIES models CM and CM-7 TWIN WIRE SLUDGE PRESS is designed to accomplish the continuous dewatering of various kinds of sludges and tailings, (i.e. pulp, municipal and industrial sludges, coal tailings) by entrainment between two porous synthetic membranes (belts). The frame may be supplied as a cantilever style to permit the use of endless as well as seamed belts. The belts are supported by either perforated plastic dewatering plates or free turning rollers throughout the unit. General construction is to the same high quality standards as other PRESS TECHNOLOGIES equipment, designed for continuous industrial service.

The material to be dewatered enters the headbox of the CM Sludge Press either directly from the source or, if chemical flocculants are used, after flocculation. The slurry is distributed across the width of the moving belt and travels along the Gravity Drainage section of the sludge press where free drainage occurs, thickening and stabilizing the material prior to entering the next section. Chicanes may be used in this section to aid in thickening and stabilizing the slurry.

After gravity drainage, the thickened slurry is deposited in the machine’s medium pressure, or Wedge Section. At this point, the top and bottom belts converge and entrap the sludge between them. The configuration of the belt support media in this section is such that pressure is constantly increased in the machine direction, ensuring continuous drainage and increased stabilization before transferring to the next stage of dewatering.

The final dewatering stage of the Twin Wire Sludge Press is the high pressure, or “S” Section. Here the stabilized sludge cake is passed in a serpentine manner between rollers of decreasing diameter, exerting both increased pressure and shear to the material for high consistency prior to discharge from the unit. As an option, press rollers can be utilized in this area to apply greater pressure to those materials amenable to it for maximum discharge consistencies.

The PRESS TECHNOLOGIES model CM and CM-7 TWIN WIRE SLUDGE PRESS has been used with great success in a wide variety of applications – from industrial and municipal waste water treatment to mining and food processing. It is a very effective tool for the economical thickening and disposal of many different kinds of slurries.

Pulp Thickening

Pressing/Wet Lapping - Standard Line

Pressing/Wet Lapping LT Line

Cuts the Sheet And Creates Pulp Bales