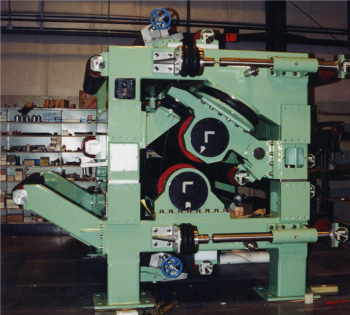

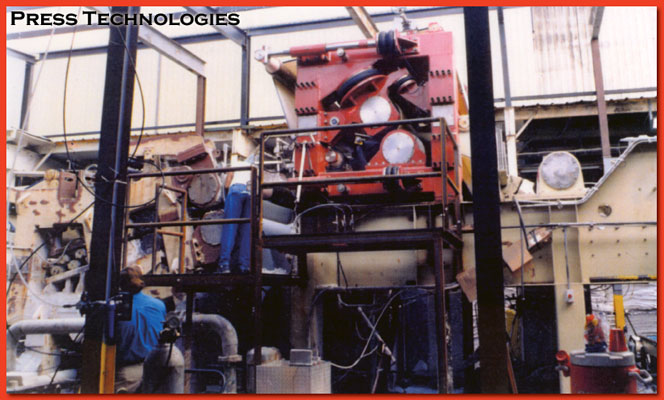

The thickened pulp sheet from a primary Twin Wire Press is transferred onto the bottom wire of the PRESS TECHNOLOGIES model HDP SECONDARY PRESS unit, and is carried up and into a set of high pressure nips. Pressure is achieved pneumatically using Firestone air bags, with a performance design pressure from 1200 to 1500 PLI depending on application. High performance roll covers are used for superior durability and performance at these high pressures. While the moisture removed in the nip will typically raise the pulp consistency anywhere from 3-8% depending on the application, it is also common to use the HDP SECONDARY PRESS as a method for increasing line production, with increases of 20-40% not uncommon.

Pressate from the driven press nips is fed into drain pans incorporated in the unit for discharge according to customer requirements. After pressing, the pulp sheet is typically discharged to a cutter layboy, a dryer, or handled in some other fashion.

After discharge, both top and bottom wires continue around the machine. They travel first through a high pressure shower unit, and then over tracking and tensioning rolls prior to beginning the cycle again.

In those applications requiring extremely high discharge consistencies or increased throughput, it should be noted that an additional HDP SECONDARY PRESS unit can also be added to the process equipment line.

Pulp Thickening

Pressing/Wet Lapping - Standard Line

Pressing/Wet Lapping LT Line

Cuts the Sheet And Creates Pulp Bales