The PRESS TECHNOLOGIES model CLB CUTTER LAYBOY unit is designed to handle the sheet discharged from either a WTPP / LTPP Twin Wire Press or HDP / LTHDP Secondary Press. After discharge from the press, the sheet is transferred onto the knife entry or transfer belt of the CLB CUTTER LAYBOY. The speed of the transfer belt is matched to the press manually or electronically depending on the capabilities of the selected drive package.

The transfer belt feeds the pulp sheet into the cutter knife, which is mounted on an independently driven roll. Speed of the knife roll is varied to determine the cut length of the sheet. After cutting, the sheets transfer onto a high speed belt which carries them over a discharge roll and slides them onto a transfer table mounted on a hydraulic scissors lift.

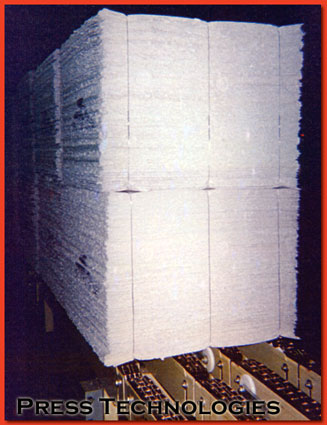

Optic sensors lower the table gradually as the stack increases in height, until a predetermined stack height is reached which triggers a set of fingers, or forks, to extend and catch the discharging sheets while the table drops to its fully lowered position and transfers the stack onto the customer’s conveyor for removal to a scale and storage or transport area. The transfer table then rises back to its topmost position and the forks retract, dropping the sheets stacked in the interim onto the table and beginning the cycle over again. The process is designed to be both automatic and continuous.

Pulp Thickening

Pressing/Wet Lapping - Standard Line

Pressing/Wet Lapping LT Line

Cuts the Sheet And Creates Pulp Bales